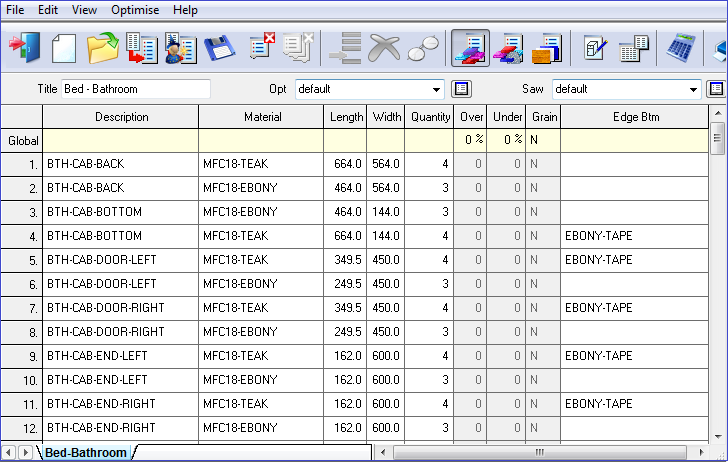

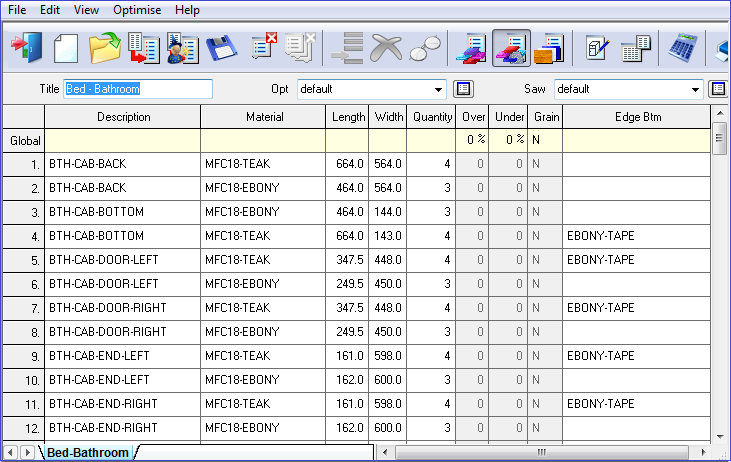

List of sizes for cutting based on an original set of sizes (usually finished sizes).

The cutting list calculation takes account of edging, trims, laminates and manual adjustments. The program always automatically creates a cutting list when optimising, recalculating runs or when the cutting list option is selected (at the Part list screen). When working at the Part list there is an option to view the linked cutting list. Where laminates and edging are used the cutting list shows the adjusted cut sizes ready for cutting.

To see the Cutting list:-

● Select: View - Cutting list

or

![]() Select the Toolbar option

Select the Toolbar option

The list can edited manually but take care when doing this as it is easy to re-generate the cutting list and lost manual changes.

Laminates - With laminates the cut size of the laminate usually includes an overlap and also depends on whether the laminate is applied before or after the edging operations.

Edging and laminating - The cutting list contains the cutting sizes for each piece and may include extra entries for cutting front and back laminates and edge pieces. Laminate codes are numbered based on the original part item number and begin with the letter L (e.g.: L0001). For laminate pieces the information boxes are often not relevant and these are set to blank where necessary.

Cutting list - access - In most cases the cutting list is created automatically from the part list before optimising but it can also be calculated and viewed from the 'Cutting list' option at the Part list screen or from the File tree at the main screen.

Once the cutting list is complete the job is ready to optimise.

● Select: Optimise - Optimise parts

or

![]() Select

the Toolbar option

Select

the Toolbar option

Cutting list rules

The cutting list is also used with the 'Cutting list options'. These are a set of custom rules and formulae that allow the part list to be automatically processed. For example to change the size of parts over 900mm by 5mm; to adjust sizes for specified parts ... It is especially useful for adjusting imported data when the imported sizes may not fully reflect the original required sizes. In these cases the cutting list holds the new calculated sizes read for optimising.

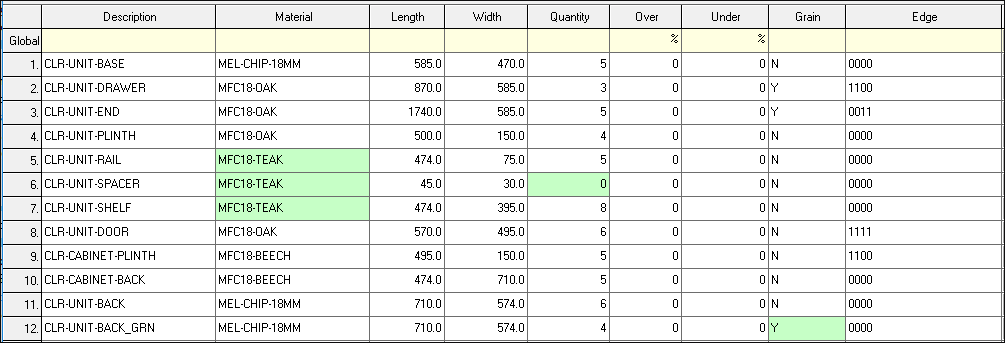

When the cutting list is generated from the part list any field changes made via the cutting list rules are highlighted with a different cell background colour.

e.g. In the below example 3 material codes, 1 quantity and 1 grain field have been changed via the cutting list rules.

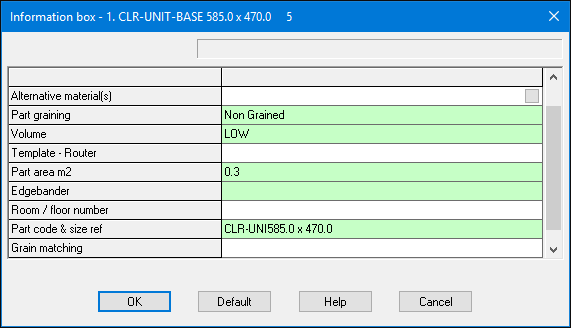

Any changes made to the information boxes via the cutting list rules are also highlighted in the information box popup dialog.

Subsequent changes to the cell will revert the background colour to white.

Notes

- The line number is used as the part description/code when the global header is a minus symbol. When the cutting list is generated the minus symbol is removed and part name is preserved even if the position in the list has changed.

- There are options in System parameters to set how the cutting list operates with edging and laminating materials and how the list is retained or deleted as data changes.