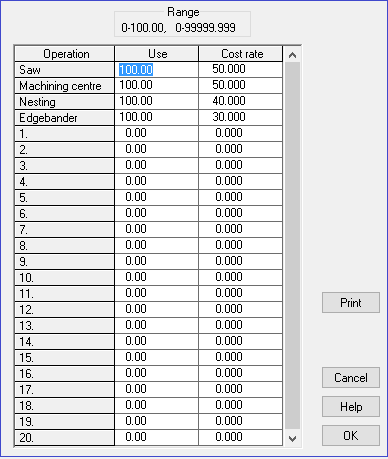

Set the values for costing

A set of parameters used to enter the machine costs for each machine or operation. At the Main screen:-

● Select: Parameters - Machine rate parameters

Program displays a grid for the Machine rate parameters

- Enter the cost rate and usage (%) for each machine or operation.

For each operation enter two values: a use and a cost rate. The use percentage represents the amount of down or slack time for a machine. For example, if the saw cutting time is calculated as 20 minutes and the machine use is 70% the actual time for the job is:-

20 x 100/70 = 28.57 mins

This adjusted time is shown on the part costing report and is the time used for costing.

Saw, Machining Centre, Nesting and Edgebander are fixed items. The other parameters can be customised to any set of machines or operations.

If a user defined operation is not defined the line shows the number of the operation. It is Ok to enter values for these un-defined operations and enter the definition later.

Custom operations - these are set via the Information Box parameter: Machine time. One parameter for each custom operation.. With these set the times for each part against each operation can be entered in the Part list or Part library.

Notes

Cost rate is to 3 decimal places

Enter the machine rate as a cost per hour and this should represent the actual cost per hour as on the costing report the time is adjusted to take account of machine usage.

Some Companies use a recovery rate for the cost of the machine per hour; which is already adjusted to take account of the down time of the machine. To use this cost instead of the actual cost per hour set the machine use value to 100%.

Both methods of working are shown in the following example:-

Using the actual cost

Labour and running costs per hour = 75 per hour

Machine use = 90%

Machine Use % Cost rate

Saw 90.00 75.00

Saw time for job = 1 hour 20mins (80 mins)

Adjusted time = 80 * (100/90) = 88.8 mins

Total saw cost = 88.8/60 * 75.0 = 111.0

Using the recovery rate

Labour and running costs per hour = L75 per hour.

Machine use = 90%

Machine Use % Cost rate

Saw 100.00 83.34

Recovery rate (cost rate = (75 * 100/90) = 83.34

Saw time for job = 1 hour 20mins (80 mins)

Adjusted time = 80 * (100/100) = 80 mins

Total saw cost = 80/60 * 83.34 = 111.0