Calculate results for several runs in one go

Batch optimisation is useful where parts lists have to be optimised in separate lists for each material; the set of runs can be kept together for analysis and optimisation. Batches can also be used to set up comparisons, for example, where the same parts list is optimised against different sets of parameters. To do this, at the Main screen:-

● Select: Review - Batch optimisation

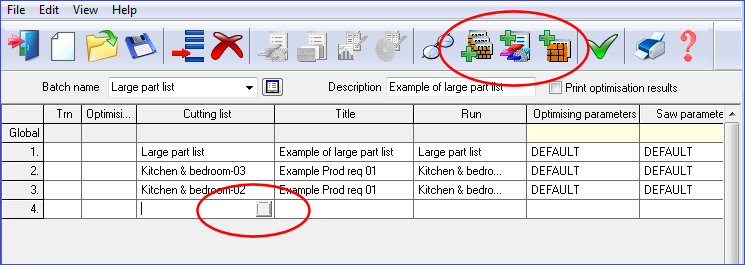

The program displays the batch screen showing the current batch.

- Use the options on the Batch screen to locate and load a different batch (which then becomes the current batch).

- Click on the grid to edit or add to the files in the batch.

Use the buttons in each column to pop up a selection list, for example, list of cutting lists, list of Optimising parameters etc. Alternatively use the Toolbar options: 'Add Optimisations' or 'Add Cutting lists'.

Print results after optimisation? - check to print the results only after all optimisation is complete

● Select: File - Continue to Optimise

or

Select

the Toolbar symbol

Select

the Toolbar symbol

The program proceeds to optimise the runs in the batch. For 'Batch optimisation' any existing results are deleted and all the runs are fully re-optimised.

Where a computer has multiple cores or multiple processors different runs can the optimised at the same time - reducing the overall optimising time. For this the Optimising parameter: Optimiser type must be set to 'Automatic selection'.

During optimisation

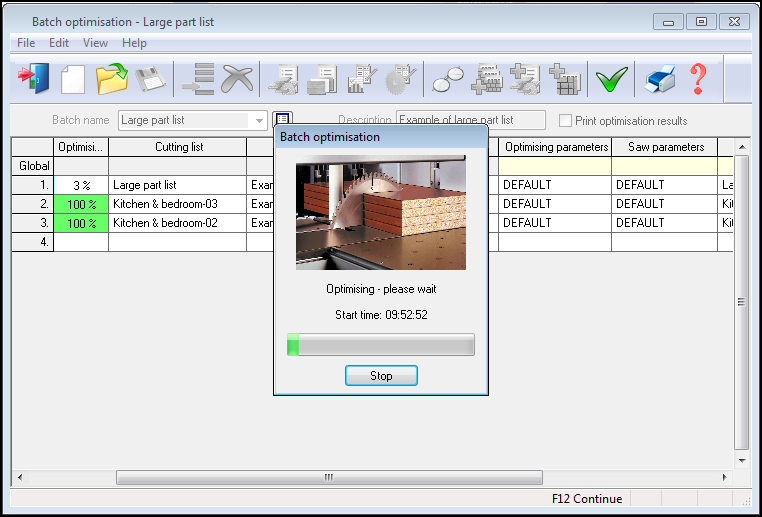

Optimising progress is shown on the batch screen. If the computer contains multiple processors (cores) the screen shows the progress of each run separtely.

[ Stop ] - halt the optimisation

The program prompts to store the results so far or to abandon the results.

Overall progress is shown in the 'Optimisation' dialog and progress for each run is shown by a colour in the grid. For example green indicates a completed run and blue a run underway.

If there is an error with a run or with part of a run the program prompts

with an error. In some cases it is possible to continue and the parts

that cannot be optimised (e.g. not enough material) are ignored. For more

serious errors the Continue button is greyed

out and the optimisation does not proceed. Check the part list, board

list and parameters to locate the problem and correct it.

If there is an error with a run or with part of a run the program prompts

with an error. In some cases it is possible to continue and the parts

that cannot be optimised (e.g. not enough material) are ignored. For more

serious errors the Continue button is greyed

out and the optimisation does not proceed. Check the part list, board

list and parameters to locate the problem and correct it.

Re-optimise

At the 'Review runs' screen (when looking at an existing batch or run within a batch) the option: File - Re-optimise is the same as 'Batch optimisation' and fully re-optimises the current batch.

Re-optimising deletes any existing changes and patterns.

The program prompts to confirm before proceeding.

Notes

Fast optimisation - multi-core or multiple processor systems

Where the computer is a multi-core or a multiple processor system the optimisers automatically take advantage of the separate processors available. Batches with more than one run or single runs with several materials can be optimised at the same time. Any reduction in overall optimising time depends on the relative size of the runs and the processors available. This option only applies when optimising is set to 'Automatic selection'. The different colours stand for:-

Optimising progress markers

Waiting to optimise

Waiting to optimise

Optimising

Optimising

Optimising finished OK

Optimising finished OK

Optimising finished - warnings

Optimising finished - warnings

Optimising finished - errors

Optimising finished - errors

Optimising messages

- With multiple processors the Optimisation dialog does not display the name of the optimisers used

- The 'Cancel' option at the 'Busy - please wait' dialog is not shown for 'Print runs' or 'Transfer runs' as these options cannot be cancelled at this point.