Parts produced from different materials

In some situations it is useful to produce the same part from different materials. For example, hidden items like backs or dividers may be produced from 12, 15, or 18mm Chipboard. This requirement is set at the Part list using the predefined Information box: Alternative material(s). If there are several different materials in a run this way of working can lead to improved yield because the parts can be spread over a wider range of boards.

To work in this way:-

● Set up the Information box: Alternative material(s)

(Main screen - Parameters - Information boxes)

See: Alternative materials information box

At the part list -

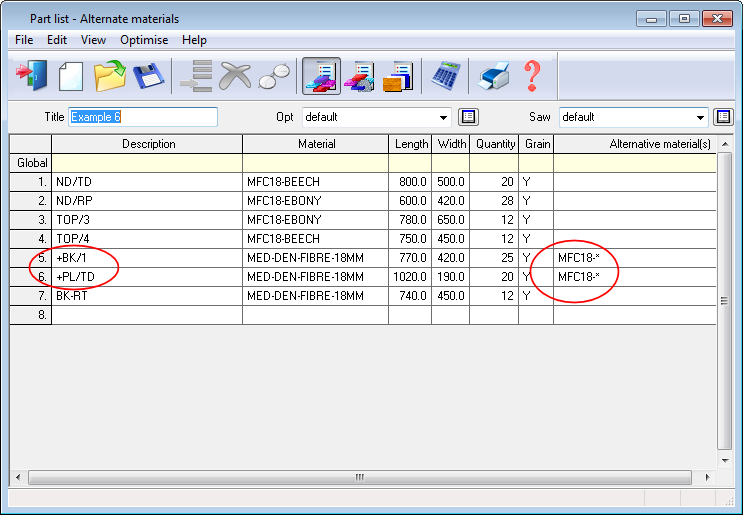

● Enter one of the materials in the Material field in the part list

● Enter the other materials in the Alternative material(s) Information box

Any parts using Alternative materials are set as Plus parts. That is, the parts can be produced from a range of materials and the quantity required is not fixed.

● Enter the main material in the 'Material' column and enter alternative materials in the information box column, for example, MFC18-BEECH. Wild card characters are allowed:-

* match with any characters e.g. CH*BOARD > CHIPBOARD or CHPBOARD

? match a single character e.g. CH?BOARD > CHPBOARD

Material codes separated by SPACE

The requirement is compared to all the materials in the Board list.

Click on the select button in the field to select via the Material dialog

Click on the select button in the field to select via the Material dialog

● Set the system parameter: Include alternative materials to determine whether alternative materials are included in the board list and whether the alternative materials are board sizes, offcut sizes, or both,

See: Include alternative materials

● Optimise in the usual way

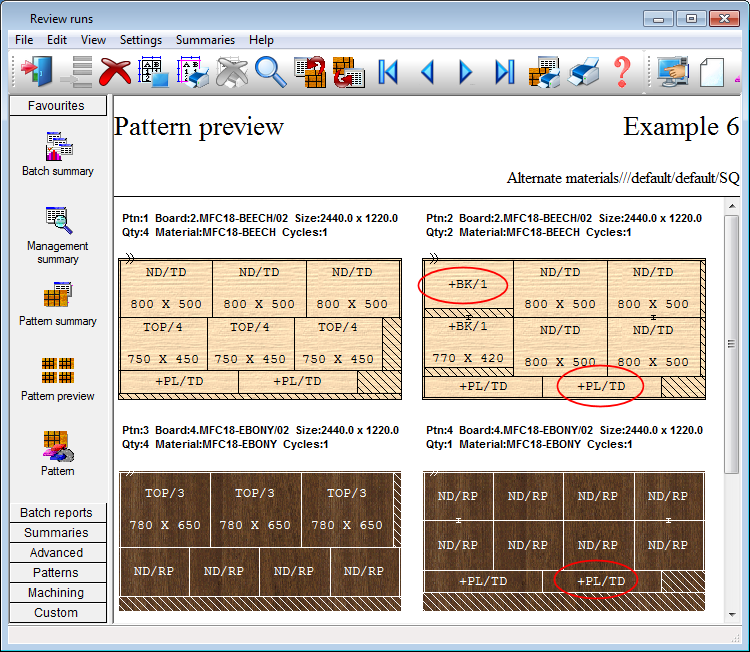

The plus parts are used across several materials.

In this case the plus part is cut from the alternative materials where there are spaces available and this minimises waste and may save boards of the main material.

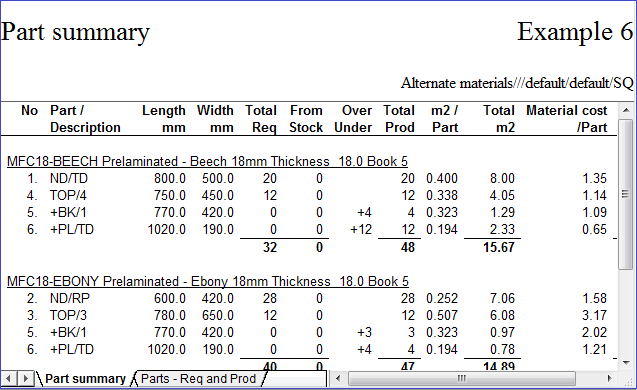

The Summary reports are adjusted to show the parts with alternative materials and the same part code may appear against different materials.

Alternative materials for non plus parts

Ordinary parts (non plus parts) with alternative materials set are optimised as plus parts for their alternative materials. For the main material, the part is optimised as an ordinary part. So if the main material is optimised first it is likely that none of the alternative materials are used for that part since the main material optimisation continues until all the quantity required are produced. In this situation the alternative materials are only used if over production is allowed. The order of materials optimised is based on the order of materials in the board list

Notes

- All parts must have a main material code set

- Not available with Nesting optimising

- Not available for Sundry parts

- The information box is a way specifying a longer list of materials to consider. All the materials in the list (including the material in the Material column) are alternatives to each other; so any or all of the materials in the list may be used.