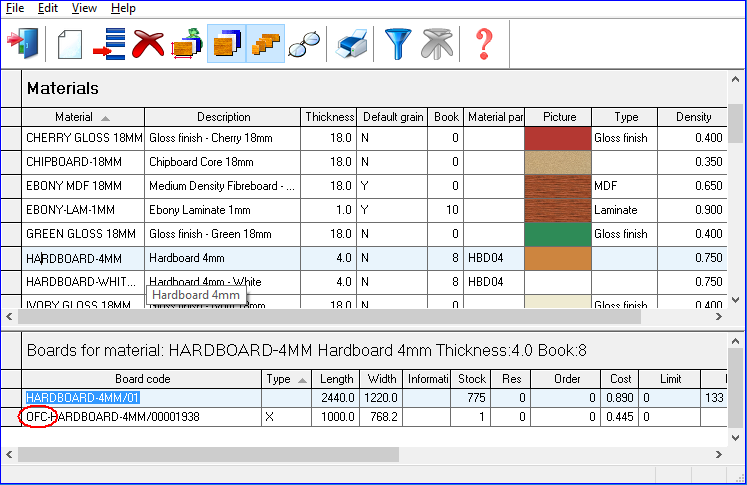

How offcuts are defined

An offcut is an unused piece of material from a set of cutting patterns which is large enough to be used in another run.

The minimum size of a useful piece (which varies from company to company) is set via: Optimising parameters (Offcuts tab). Once this is set the program produces and shows any offcuts on each pattern.

(On this page of the optimising parameters there are also several other settings to control how offcuts are created and used.)

See: Minimum offcut length, width area

Each offcut created as part of the optimisation and can be transferred back to the Board library (as required); the Offcut report can be printed and the offcut dimensions can be transferred to the saw.

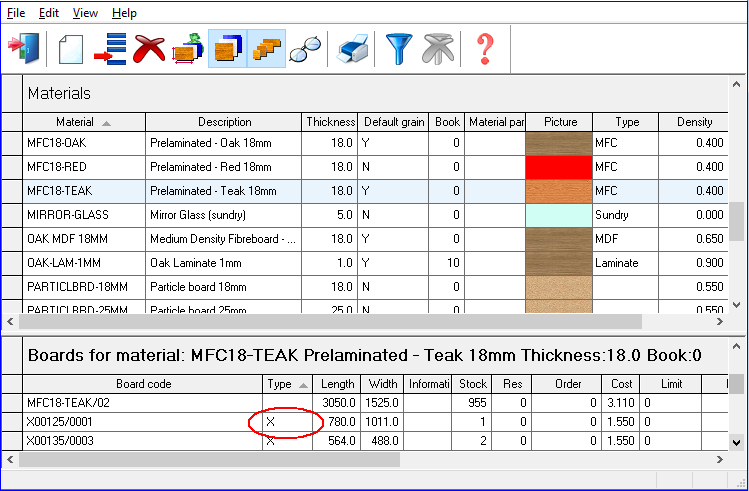

Offcuts are identified via field in the board library (and Board list); 'Type'. This can be set to blank for a stock board and 'X' to indicate an offcut. The options are: Stock board or Offcut.

See: Board type

The board code can optionally include a prefix to indicate an offcut. This is set by the system parameter: 'Offcut name prefix'

See: Offcut name prefix

When an optimisation is confirmed the board library can be updated via the Stock menu (Issue stock for runs) this removes any boards used in the optimisation from the library and adds back in any new offcuts created.

There are two methods for labelling offcuts. A sequential number or a combination of the run number and position of the offcut in the run. For example:-

OFC-00042359 OFC-00021/0003

OFC-00042360 OFC-00021/0004

OFC-00042361 OFC-00021/0005

The cost of an offcut is set as a percentage of the original board cost (set via System parameters) and the cost can also be entered directly at the Board library. (There are several other settings to control offcuts on the 'Rules 2' tab of System parameters).

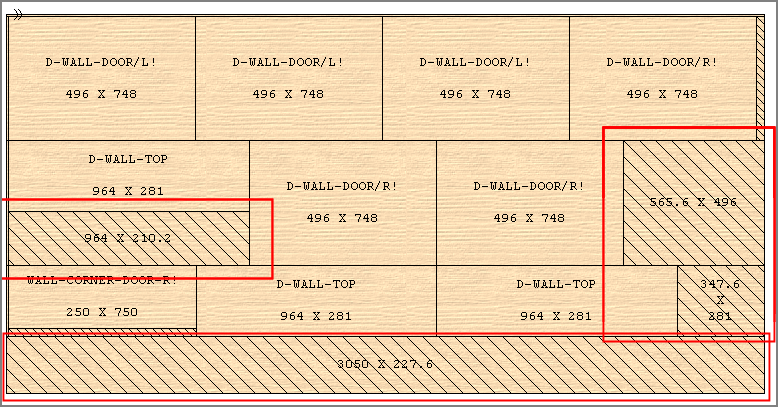

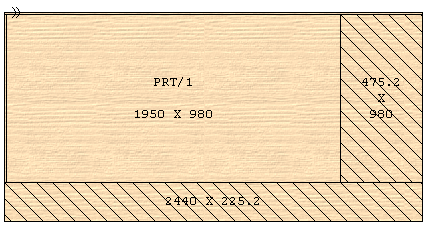

Offcut dimensions

By default the offcut length is taken as the longest edge. The offcut dimensions are shown in the Offcut summary and are transferred to the saw.

In the above example the offcut at the right is taken as and transferred as: 980.0 x 475.2.

(The label on the pattern follows the orientation of the piece on the pattern drawing and does not necessarily reflect how the dimensions are shown in the Offcut Summary and/or transferred to the saw).

For a grained material (as above) this may not preserve the orientation of the length along the grain. The optimising parameter: Always preserve offcut orientation can be set to avoid this problem. If the parameter is set the offcut is taken as 475.2 x 980.0.

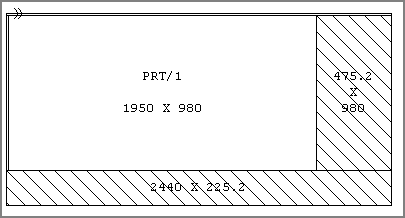

For a non-grained board the same default rule applies; the offcut dimension is taken as the longest dimension. The offcut at the right is taken as and transferred to the saw as: 980.0 x 475.2

Where the optimising parameter: Always preserve offcut orientation is set the offcut is taken as the offcut edge which is parallel to the board length (as defined in the cutting list). The offcut at the right is taken as and/or transferred to the saw as: 475.2 x 980.0

If the board orientation is rotated for cutting this does not affect how the dimensions are calculated and sent to the saw.

Nesting

For the Nesting optimiser there are a separate set of parameters to define and control offcuts because they operate slightly differently with shaped parts but Offcuts are stored in the board library in the same way using the above rules and settings.

See: Nesting parameters - Overview