System parameter to select how offcuts are labelled

Each offcut generated in a run is given a unique code. This code is used to identify the offcut on reports and in the board library. There are several options:-

Run name and sequence in the run

Sequential number

Material code and sequential number

Board code and sequential number

Select the radio button to choose an option

Select the radio button to choose an option

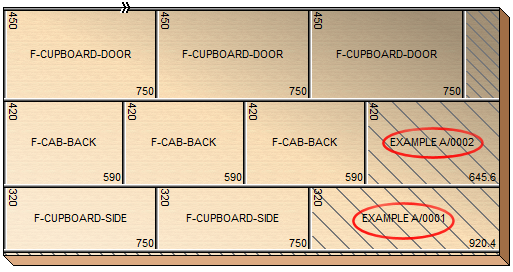

Run name and sequence in run

With this option the code is created from a combination of the run number (5 digits) and the position of the offcut in the run (4 digits). For example:-

EXAMPLE A/0001

EXAMPLE A/0002

...

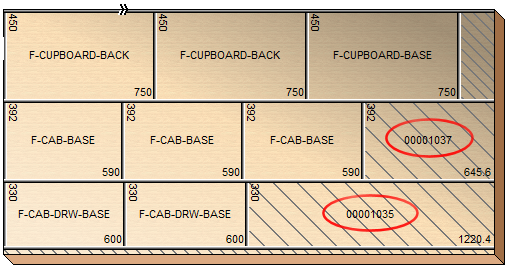

Sequential number

With this option the code is created as a single sequential number (maximum 8 digits). For example:-

00001035

00001036

00001037

...

The last number used is shown (and can be set by) the System parameter: Last offcut number

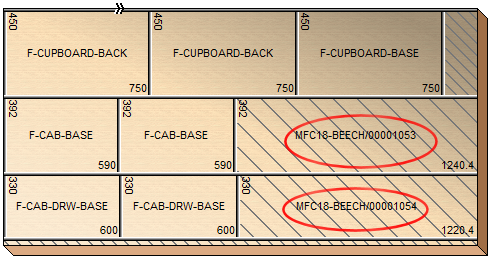

Material code and sequential number

With this option the code is created from a combination of the material code and a single sequential number (maximum 8 digits).

MFC18-BEECH/00001053

MFC18-BEECH/00001054

...

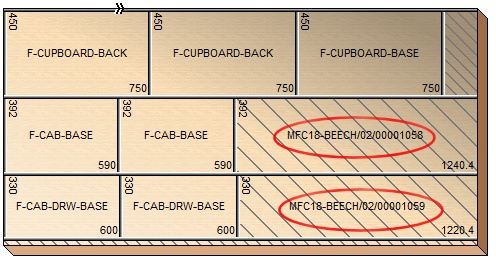

Board code and sequential number

With this option the code is created from a combination of the material code and a single sequential number (maximum 8 digits).

MFC18-BRD1/13744

MFC18-BRD2/13745

...

Unique names

Where there is a stack height of more than 1 the offcut label applies to all the similar offcuts in the stack. For example with a stack height of 5 the offcuts produced are:-

Label Qty

00021/0001 5

00021/0002 5

For some methods of production a unique name is required for every single offcut piece.

See the System parameter: Single quantity offcuts with unique names |

Offcut prefix

An offcut code can optionally have a prefix (e.g. X00021/001, OFC-MFC18/13721).

See: Offcuts |

Separator

Use the System parameter: Offcut separator to specify the separator between the code and sequential number.

| See: Offcut names separator |

|

|