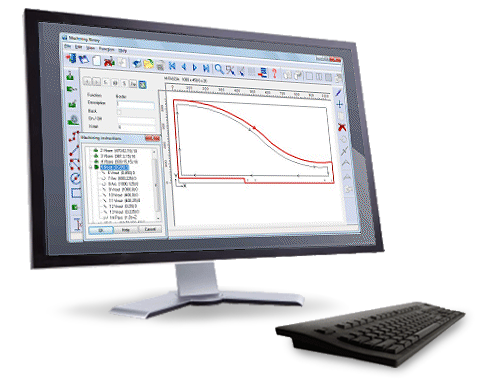

Machining Interface

For fast setup of your CNC machinery

To streamline production into a seamless highly efficient and accurate process, simply use the machining interface feature. It creates a fully integrated manufacturing cell, by downloading part drawings directly to your point-to-point machining centre.

Parts are labelled at the saw with a bar code for the drawing reference; scanning at the machining centre provides a foolproof and fast process that guarantees each part is machined correctly.

Highlights

- The geometry for rectangular or shaped parts can be drawn quickly using the editor, or can be imported from DXF files.

- The machining library holds parametric drawings so that as the part size changes, the machining instructions are recalculated instantly.

- Offers support for drilling, grooving, contour routing, operations on both sides of part, vacuum pod positions, dimension lines and pockets.

- Details of depths and tooling information can be added for each operation, including tool speeds, tool path compensation and other tool specific data.

- The machining interface allows direct transfer of data to most CNC-controlled machining centres via DXF and proprietary formats.

- Labels or route sheets can include the part drawing, and machining times can be estimated for each part.

Magi-Cut is such a powerful tool

It not only optimises the boards and material required, it can output all CNC programs required and send the cutting pattern to the saw. This eliminates a lot of human error associated with multiple tasks that can all be centrally controlled and out-put through Magi-Cut saving time and money

Mark Horn - Ruddy Joinery

Printer friendly info